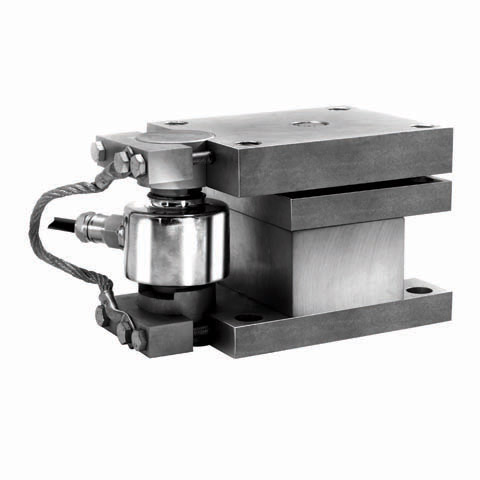

ADVANTAGE® HI LPRC03 low profile, rocker load point systems are specially designed for high capacity hopper and tank weighing. Easy to install by bolting or welding, they have a low profile and 200% safe load limits. Each rocker load point consists of either plated, cast, or stainless steel mounting hardware and a stainless steel mV/V & mV/V/ohm matched load sensor with true hermetic sealing, Hardy’s exclusive C2® calibration, a ¼ NPT conduit adapter, and 30 feet of cable for 110K and less and 50 feet of cable for 220K and above.

Each assembly provides built-in checking, lift off protection, and is specifically designed to eliminate the effects of unwanted forces to provide exceptionally accuracate load cells. A grounding strap, fixed color code wiring label, and installation manual are provided with each load point. The sensors have an IP rating of IP68/IP69K. The HI RCH03 load cell is certified to NTEP Class III.

The HI LPRC03 rocker load point assembly is available in the following standard capacities: 16.5K, 33K, 50K, 66K, 88K, 110K, 220K, 330K, and 660K lbs.

Dummy load cells are available for both the RCH03 and RCH04 sensors. Dummy load cells have the same mounting and load introduction characteristics as the cell it replaces. These are used as intermediate placeholders in weighing systems that are being worked on (i.e. welding, painting, and moving vessels), and those that require input and output apparatuses in any given application. Dummy load cells provide level control and are usually used to stand in for self-aligning load points that require dry runs of the system prior to complete operation.

MAXIMUM CAPACITY (Emax) IN Klbs: 16.5K / 33K / 50K / 66K / 88K / 110K

- Maximum number verification intervals (nmax): 3,000

- Minimum load cell vertifcation inteval (vmin): Emax/15,000

- Combined Error (%RO): ± 0.0200

- Non-Linearity (%RO): ± 0.01666

- Hysteresis (%RO): ± 0.01666

- Creep Error (30 minutes) /DR (%RO): ± 0.01666

- Temperature effect on min dead load output (%RO) /10°C: ± 0.0093

- Temperature effect on sensitivity %RO/10°C: ± 0.0100

- Rated Output (%RO) mV/V: 2 ± 0.1

- Calibration in mV/VO: Matched

- Zero Balance (%RO): <± 5

- Excitation Voltage (V): 5-15

- Input Resistance(W): 1150 ± 50

- Output Resistance(W): 1000 ± 2

- Insulation Resistance(100VDC) (MW): ≥5000

- Excitation voltage: 5-15 VDC

- Load Cell Safe Load Limit(% Emax): 200

- Load Cell Ultimate Load Limit (% Emax): 300

- Load Cell Safe Load Limit (% Emax): N/A

- Minimum load cell verification interval (vmin): N/A

Environmental Specifications

- Temperature effect on min dead load output (%RO) /10°C: ± 0.0400

- Temperature effect on sensitivity %RO/10°C: ± 0.0200

- Load Sensor Material: Stainless Steel 17-4 PH (1.4548)

- Sealing: Complete Hermetic Sealing -- Glass to Metal Header

- Protection According to EN 60529: IP68 (up to 2m water depth/IP69K

- Cable Length: 30 ft

- Hazardous Certification: IS Class 1,2,3 Div 1, NI Class 1,2,3 Div 2

- Legal for Trade: N/A

MAXIMUM CAPACITY (Emax) IN Klbs: 220K/330K/660K

- Maximum number verification intervals (nmax): N/A

- Minimum load cell vertifcation inteval (vmin): N/A

- Combined Error (%RO): ± 0.0500

- Non-Linearity (%RO): ± 0.0400

- Hysteresis (%RO): ± 0.0400

- Creep Error (30 minutes) /DR (%RO): ± 0.0600

- Temperature effect on min dead load output(%RO) /10°C : ± 0.0400

- Temperature effect on sensitivity %RO/10°C: ± 0.0200

- Rated Output (%RO) mV/V: 2 ± 0.1

- Calibration in mV/VO: Matched

- Zero Balance (%RO): ± 5

- Excitation Voltage (V): 5-15 VDC

- Input Resistance(W): 1150 ± 50

- Output Resistance(W): 1100 ± 2

- Insulation Resistance(100VDC) (MW): ≥5000

- Load Cell Safe Load Limit(% Emax): 200

- Load Cell Ultimate Load Limit (% Emax): 300

- Load Cell Safe Load Limit (% Emax): N/A

Environmental Specifications

- Compensated Temperature Range: 14° F to 104° F (Minus 10° C to Plus 40° C)

- Operating Temperature Range Minus 40° F to Plus176° F (-40° C to +80° C)

- Load Sensor Material: Stainless Steel 17-4 PH (1.4548)

- Sealing: Complete Hermetic Sealing -- Glass to Metal Header

- Protection According to EN 60529: IP68 (up to 2m water depth/IP69K

- Cable Length: 50 ft

- Hazardous Certification: IS Class 1,2,3 Div 1, NI Class 1,2,3 Div 2

- Legal for Trade: N/A

All specifications are subject to change without notice.

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including C2® electronic calibration, and Integrated Technician® to name just a few.

Hardy load cells support the following Hardy Process Toolbox functions when coupled with a Hardy Instrument and Hardy C2® cable.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.