Newer Models Available! HI6800

HI6800

HI6850

General Purpose Weight Controller

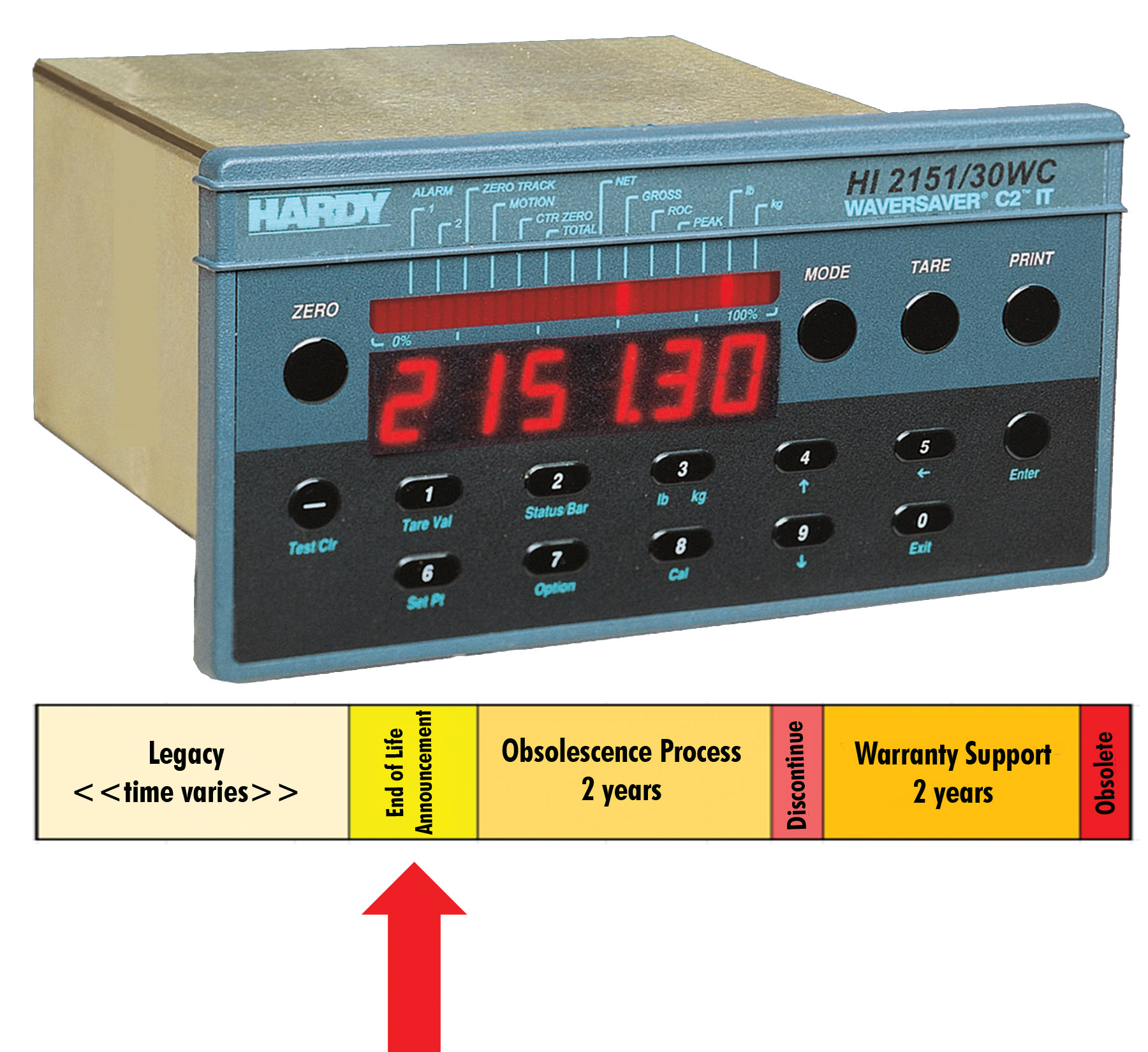

The HI 2151/30WC is used for a wide variety of process weighing applications including batching, blending, check weighing, filling/dispensing, force measurement, level by weight, and weight rate monitoring.

Notice for Non-RoHS Compliant Construction

As a stand-alone product, the HI 2151/30WC can control as many as eight set point relays, (2 standard form C) and transmit data via analog, serial, Profibus DP, or BCD communications. Data is displayed alpha-numerically on the six digit fourteen segment LED display and graphically on the 30 segment bar graph display. Weight values can be based on either Net, Gross, Rate-of-Change (ROC), Peak Hold, or Totalized weight values in pounds or kilograms.

The HI2151/30WC weight controller can also be used as a front end for a manufacturing control system, transmitting weight values via a standard operator selectable serial port (RS-232, RS-422/485) and interface with programmable logic controllers (PLCs), computers, and printers. Also available are optional Analog, and Profibus interfaces for communication to programmable logic controllers.

A 20-bit analog to digital converter in the weight controller updates twenty (20) times per second and is capable of 985,000 counts of display resolution. This gives the instrument the ability to tolerate large “dead” loads, over sizing of load cells/sensors, and still have sufficient resolution to provide accurate weight measurement and control. Commands can be entered into the instrument from the communication ports or locally from the front panel keypad. A portion of the keys can be locked out to limit operator access and protect data.

Hardy’s process weighing solutions are easy to install, configure, commission, and operate. They are easy to maintain and save you time, money, raw materials, and/or finished product. Visit our case studies or application notes to learn more.

HI 2151/30WC

Display

- Alpha-numeric: 6 digit, 14 segment red LED

- Bar Graph: 30 segment LED

Update Rate

- 20 times per second

Averaging

- Sliding up to 200 readings in single unit increments

Resolution

- Display: 1:985,000 (3mV/V load cells)

- Internal: 1:1,048,000

Accuracy

- 0.0015% non-linearity

Stable Weight Reading

- WAVERSAVER® 0.25Hz minimum

Calibration Techniques

- C2® electronic calibration

- Traditional calibration with test weights

- Soft Calibration with manual input of load cell data

Setpoints

- Two internal Form C relays

- Setpoint (target weight)

- Preact (trip point)

- Deadband (reset)

- 115 VAC, 3 amp, Form C

Data Security

- Secure Memory Module (SMM)

Built In Diagnostics

- INTEGRATED TECHNICIAN (IT)®

Load Point Excitation

- 5 VDC internal power supply to drive up to eight 350-ohm load cells

Standard Networking Options

- RS 232: Full duplex (-A1)

- EIA 422: Full duplex (-A2)

- EIA 485: Half duplex (-A3)

- Hardy Link LAN

Common Mode Rejection

- 100 dB at 50-60 Hz

Power Requirement

- 120/240 VAC, ±10 %, 47-63Hz

- 10 watts with options installed

Operating Temperature

- -10° to +50°C (14° to 122°F)

Humidity

- 0-90% non-condensing

Inputs

- 8 remote functions

Approvals

- NTEP, Canada Weights & Measures

- Hazardous Area FM Class I, II, III Div. 2 Groups A-G

- UL

Warranty

• Two-year warranty against defects in workmanship

All specifications are subject to change without notice. Please contact the Hardy factory or visit our website for the latest specifications.

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 2151/30WC features the following Toolbox technologies:

WAVERSAVER® vibration eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

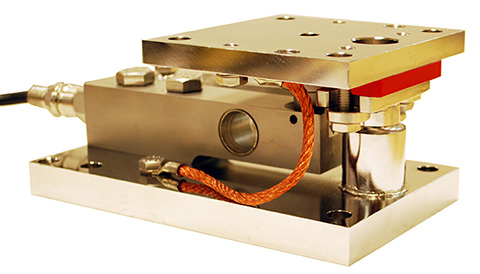

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

Secure Memory Module Stores Configuration Data

For the HI 2151/30WC, Hardy's Secure Memory Module (SMM) is a proprietary card used to automatically back up critical weighing system data, allowing you to transfer it to another like controller in a few minutes.