New Modernized HI6501 Weight Processor

Learn More!Solution for pharmaceutical company reduces waste of expensive materials

A pharmaceutical company needs to ensure that a large stainless steel bin holding drug products is completely empty before washing the bin, since the products often stick to the sides of the bin even after vibrating and hammering the vessel. “The residual material is expensive and represents a loss in revenue for us,” states the customer. Besides, environmental regulations do not allow dangerous chemicals to go down the drain. Finally this application requires a different type of load cell since each time the robot drops the bin on the bin washer conveyer, this causes a significant shock to the load cells.

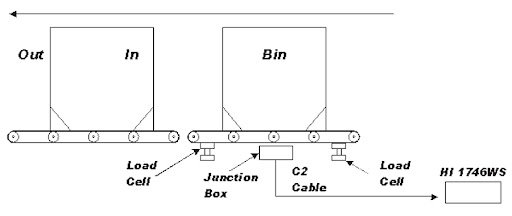

Oversized ADVANTAGE® load cells with custom-made mounts to fit the existing gap in the structure (see illustration) are installed to allow for the shock loading, while still being able to provide accurate weigh measurement to meet the required tolerance. The weight data is sent to the yield check system to meet a programmed threshold before going onto cleaning. An HMI is used for local display, calibrations and diagnostics.

This self-checking system prevents the waste of very expensive and potentially hazardous pharmaceutical materials from being washed down the drain. “We now know the bin is empty rather than having to guess,” says the operator.