Certified DeviceNet Compliant

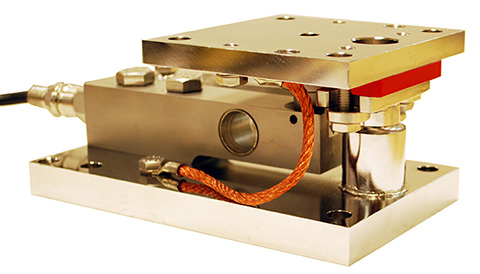

Hardy's HI 200DNWM is the first general purpose weigh module designed specifically to the DeviceNet open network standard, and the first to pass conformance testing at one of ODVA's independent laboratories. This instrument provides power for up to four, 350 ohm, standard strain gauge load cells, load sensors, and load points.

Notice for Non RoHS Compliant Construction

The HI 200DNWM receives and digitizes the weight signal and transmits Gross, Net, and Tare weight data over the DeviceNet open network interface to other devices. Two independent TTL level outputs provide setpoint capability with separate deadbands and preacts for use in applications such as batching, blending, filling, dispensing, level, and check weighing. It responds to both Command Interface (discrete) and Explicit (block) messages.

When the HI 200DNWM is used with C2® certified load cells, THE BUTTON allows the system to be automatically set up, calibrated, and online in a matter of seconds, reducing the system start up time and costs. Hardy's exclusive WAVERSAVER® feature eliminates the effects of plant and process vibration.

This instrument was the first DeviceNet weighing module to be referenced by Rockwell Automation's Encompass program. Contact us today to integrate weighing into your DeviceNet application!

Power

- Provided from the backplane of the rack: +5Vdc

Backplane Current

- < 0.5 Amps @ 5Vdc

Inputs

- Signal, -0.3mV through +15.3 mV

- Sense, +5Vdc

- C2® Electronic Calibration Diagnostics data

Outputs

- Excitation 5Vdc

Common Mode Rejection

- 100dB at or below 60 Hz (minimum)

Resolution

- Internal, 1:8,388,608

Vibration Frequency Rejection

- 0.25 Hz and above in 5 selectable steps

- WAVERSAVER®

Weight

- 0.6 lb (0.27 kg)

Environmental Conditions

- Operating Temperature: 0 to 60°C(32 to 140°F)

- Storage Temperature: -40 to 65°C(-40 to 185°F)

Relative Humidity

- 5 to 95% (non-condensing)

Weighing Modes

- Net, Gross, Rate-of-change

Calibration

- Electronic (C2)

- Traditional (test weights)

Conversion Rate

- Up to 100 updates per second

Indicators

- “OK” Module Status, bi-color LED

- “Scale 1” Functional Data, bi-color LED

- “Scale 2” Functional Data, bi-color LED

Warranty

- Two-year warranty against defects in workmanship

Specifications are subject to change without notice.

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 200DWDM features the following Toolbox technologies:

WAVERSAVER® Vibration Eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.