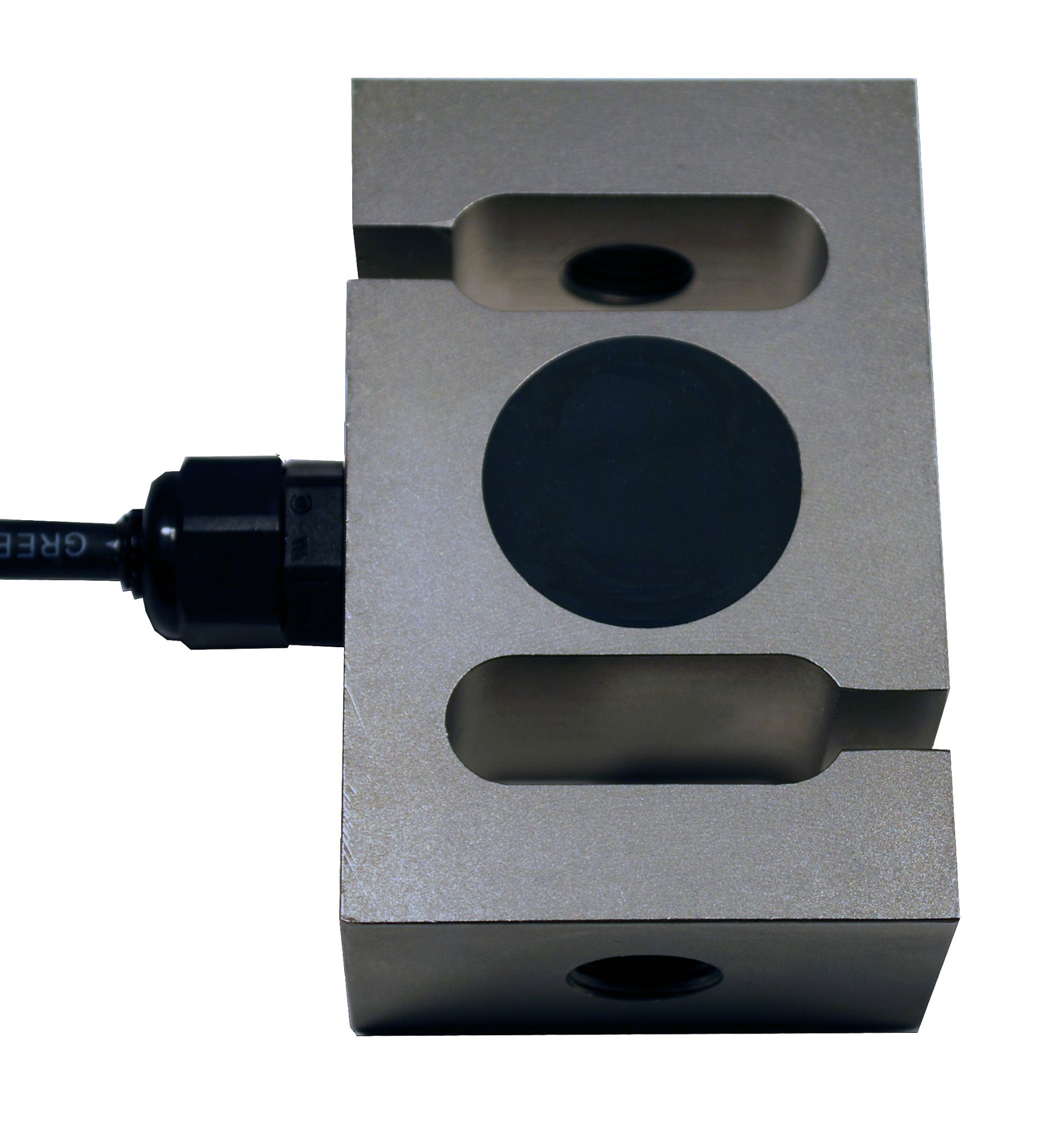

The Hardy Process Solutions HI STLB Advantage® Lite ‘S’ Type stainless steel sensor is designed for hanging vessels, hoppers, filling machinery, and process control. These stainless steel 17-4PH sensors feature IP67 ratings and allow for tension and compression loading. Improved potting makes it suitable for use in industrial environments. It features the same load cell accuracy and performance as their Advantage counterpart, but without hermetic sealing.

Sensors come with Hardy C2® electronic datasheets to support weightless calibration capabilities when coupled with a Hardy weighing instrument. They are available in a wide range of capacities from 100 kg to 5000 kg (220 lbs to 11Klb).

The HI STLB sensor can be used standalone using a threaded rod or with the same clevis mount used on the HI HLPT load points. The HI LPTLB tension load cell is available in capacities from 220lb (100kg) to 11Klb (5000kg). The sensor is environmentally protected with a plastic covering to IP67. The tension load cell provides a robust, accurate solution for general tension-mounted industrial weighing applications.

A grounding strap and fixed color code wiring label are provided with each load point. The mounting hardware is available in either stainless or galvanized steel. The Load Cell cable is 20 ft.

The Hardy Process Solutions HI STLB Advantage® Lite ‘S’ Type stainless steel sensor is designed for hanging vessels, hoppers, filling machinery, and process control. These stainless steel 17-4PH sensors feature IP67 ratings and allow for tension and compression loading. Improved potting makes it suitable for use in industrial environments.

SPECIFICATIONS HI STLB

Rated Output (ES)

2 + 0.1% mV/V

Max # Verification Int.

3000

Min Verification Int.

Emax/12000

Non-Linearity

<±0.0166 % R.O.

Hysteresis

<±0.0166 % R.O.

Zero Balance

<±5.0 % R.O.

Combined Error

<±0.02 % R.O.

Creep @ 30 Min.

<±0.0166 % R.O.

Temp Effect Output

±0.0116% RO/10°C

Temp Effect Sensitivity

±0.010 % RO/10°C

Input Resistance

1100±50 ohm

Output Resistance

1000 ± 2 ohm

Insulation Resistance

≥5000 Mohm

Excitation

5 - 15 vdc

Safe Load Limit

200 % Emax

Ultimate Load

300 % Emax

Sensor Material

Stainless Steel 17-4PH

Sealing

Potted

Approvals

CE, IP67

Warranty

Two years

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including C2® electronic calibration, and Integrated Technician® to name just a few.

Hardy load cells support the following Hardy Process Toolbox functions when coupled with a Hardy Instrument and Hardy C2® cable.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.