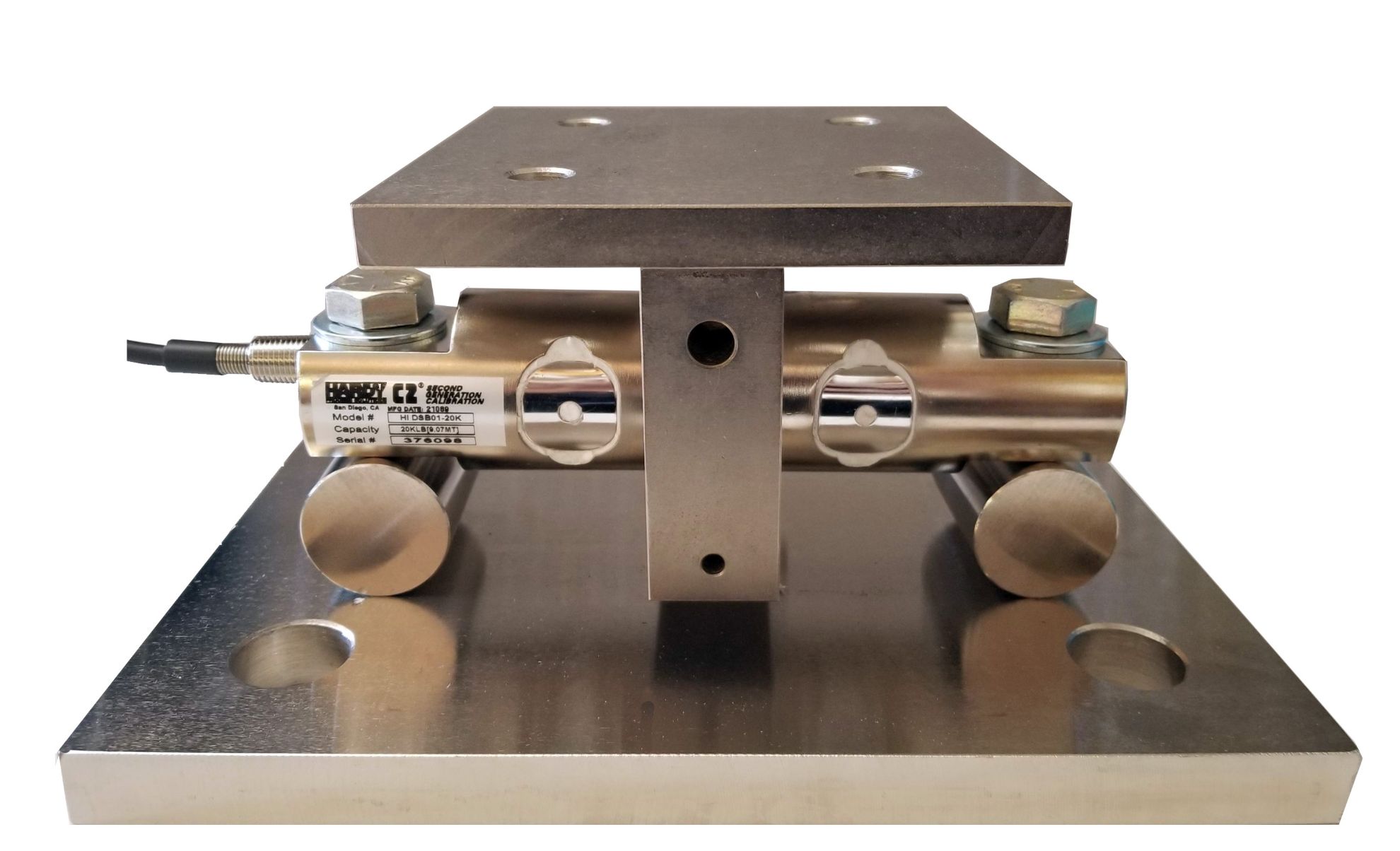

The Hardy HIDSB01 and HIDSB02 Double Ended Shear Beam load cells are designed for use on medium to high capacity tanks, hoppers or vessels. This series offers high accuracy and reliable performance with Hardy’s industry leading C2® Electronic Calibration technology.

Ideal for high capacity tanks and vessels, the Double Ended Shear Beam series are dependable workhorses suitable for heavy duty applications. The load cells and mounts come in either alloy steel (HIDSB02) or stainless steel (HIDSB01) construction. Both Stainless Steel and Nickel plated alloy steel come in 5Klb to 200Klb (2.27 to 113.4 Metric Tons), with mounting hardware available separately.

They are oil proof, waterproof and non-corrosive, making them suitable for all kinds of environments. They have a protection rating of IP67. Both series come with a 9m (30 ft) cable.

Hardy Double Ended Shear Beam load cells are designed for use on medium to high capacity tanks, hoppers or vessels. This series offers high accuracy and reliable performance with Hardy’s industry leading C2 Electronic Calibration technology.

HIDSBMT Mounting Hardware

Capacity kbs t* Mount Model#

5-20 klb 2.27 to 9.07 t HIDSBMT-_S-5-20KLB**

30-75 klb 13.6 to 34.02 t HIDSBMT-_S-30-75KLB

100 klb 45.36 t HIDSBMT-_S-100KLB

150 klb 68.04 t HIDSBMT-_S-150KLB

200-250 klb 90.72 to 113.4 t HIDSBMT-_S-200-250KLB

SPECIFICATIONS - HIDSB01 Load Cell

Capacities - 5K, 10K, 20K, 40K, 50K, 60K, 100K, 150K, 200K

Rated Output (ES) - 3.0 mv/v ± 0.10%

Zero Balance - <±1.0 % Rated Output

Hysteresis - < 0.02% Full Scale

Non Linearity - < 0.03% Full Scale

Combined Error - <±0.02% R.O.

Input Resistance - 700±7 ohm

Output Resistance - 703 ± 4 ohm

Excitation - 0VDC - Maximum 15VDC

Safe Load Limit - 50% Emax Sensor

Material - Stainless Steel 17-4PH

Temperature - Compensated 0 - 150 deg. F

Temperature - Effect on Zero < 0.0011% FS O/deg. F

Sealing - Potted

Approvals - CE, IP67

Warranty - Two years

SPECIFICATIONS - HIDSB02 Load Cell

Capacities - 5K, 10K, 20K, 40K, 50K, 60K, 100K, 150K, 200K

Rated Output (ES - 3.0 mv/v ± 0.10%

Zero Balance - <±1.0 % Rated Output

Hysteresis - < 0.02% Full Scale

Non Linearity - < 0.03% Full Scale

Combined Error - <±0.02% R.O.

Input Resistance - 700±7 ohm

Output Resistance - 703 ± 4 ohm

Excitation - 10VDC - Maximum 15VDC

Safe Load Limit - 150% Emax Sensor

Material - Nickel Plated Alloy Steel

Temperature - Compensated - 0 - 150 deg. F

Temperature - Effect on Zero - < 0.0011% FS O/deg. F

Sealing - Potted

Approvals - CE, IP67

Warranty - Two years