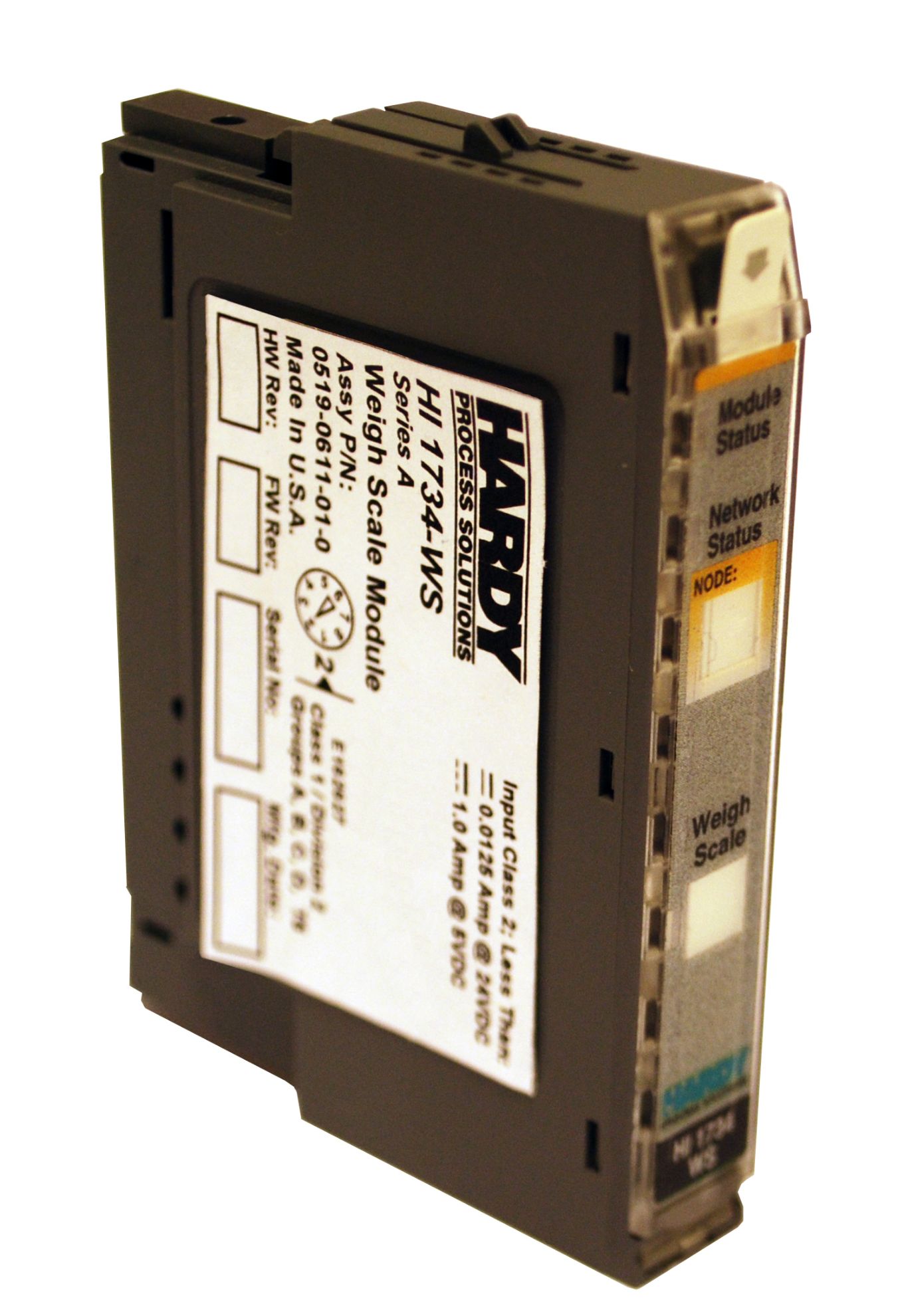

The Hardy HI 1734-WS Point I/O Series Weight Processing Module is a new plug-in module for Rockwell Automation’s Point I/O chassis, the fastest growing segment of Rockwell controllers. The HI 1734-WS is a true weight processing module, compared to competitive offerings that merely pass weight data through to the PLC for interpretation. It has a Rockwell Add-on-Profile (AOP) that will automatically recognize the module when it is plugged into the Point I/O chassis.

The Hardy HI 1734-WS module is ideal for applications stable weight data and low cost of ownership are critical components to successful machine and process design. Designed exclusively for weight processing in POINT I/O products such as communication interface modules and terminal bases from Rockwell Automation, the HI 1734-WS enhances the productivity of manufacturing systems by digitally suppressing noise and dramatically reducing scale settling time.

- Easy to mount, set up, calibrate and maintain

- Rockwell’s Adaptor Products allow connectivity to EtherNet/IP, DeviceNet, and ControlNet in linear, star, and ring topologies

- Ultra-compact at just a ½” wide, the HI 1734-WS module saves cabinet space over the use of dedicated instrumentation, reducing both machine cost and control cabinet footprint

- Up to 8 350 Ω per weight processing module

- Consumes just one watt when powering a Hardy IT junction boxes and up to 4 load cells

- A Rockwell Add on Profile (AOP) and Faceplate with Add-on-Instructions (AOIs) make it easy to integrate the HI 1734-WS into the manufacturing process control applications of a Rockwell controller with no programming required

- Features Hardy Process Toolbox features, including C2® weightless calibration, Integrated Technician™ Diagnostics, and WAVERSAVER® mechanical noise suppression

Performance

Resolution

- Stable processed weight 1:10,000

- Internal resolution 1:8,388,608

Update Rate

- Processed weight, display, communications: 55 times per second

- Unprocessed weight (A/D conv.): 4800 times per sec

Modes

- Gross, Net

Units of Measure

- Ounce, Pound, Ton, Gram, Kg, Metric Ton

Weight Processing

- WAVERSAVER®: 1.0 Hz to 7.5 Hz

- Averaging:1 to 255 User-selectable in single increments

Calibration Methods

- C2® calibration without test weights

- Traditional calibration with test weights

Output

- Excitation 5VDC

Inputs

- Signal, -0.3 mV to +15 mV

- Sense, +5 Vdc

- C2®, Electronic Calibration

Number of Load Cells

- Up to 8 350 Ω per weight processing module

Mounting

Compatible with the following Terminal Bases*

- 1734-TOP3 (12-terminal screw-clamp, one piece)

- 1734-TOP3S (12-terminal spring-clamp, one piece)

- 1734-TB3 (12-terminal screw-clamp, assembly)

- 1734-TB3S (12-terminal spring-clamp, assembly)

*See Allen-Bradley POINT I/O Module Bulletin for proper installation instructions

Environment

- IP-30 rated housing

- High Strength ABS-Polycarbonate Blend

Power

- Provided by 1734 backplane: 5 VDC, 100 mA

- 24 VDC, 100 mA

Temperature

- -20°C to +55°C (-4° F to 131°F)

Humidity

- 0-90% non-condensing

Dimensions

- 4.57”(11.6cm)D x 4.76"(12.1cm)H x 0.5”(3.2cm)W

Humidity

- 0-90% non-condensing

Certifications

Safety

- UL & CUL

- RoHS3 and REACH Compliant

Hazardous

- Class I/Div2 Groups A, B, C, and D

Warranty

- Two-year warranty against defects in workmanship

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 1734-WS Weigh Scale Module for POINT I/O Systems features the following Toolbox technologies:

WAVERSAVER® Vibration Eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

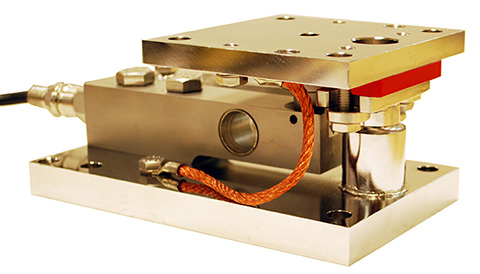

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.