Accurate, Stable, and Fast Weight Readings in an Ultra Compact Package

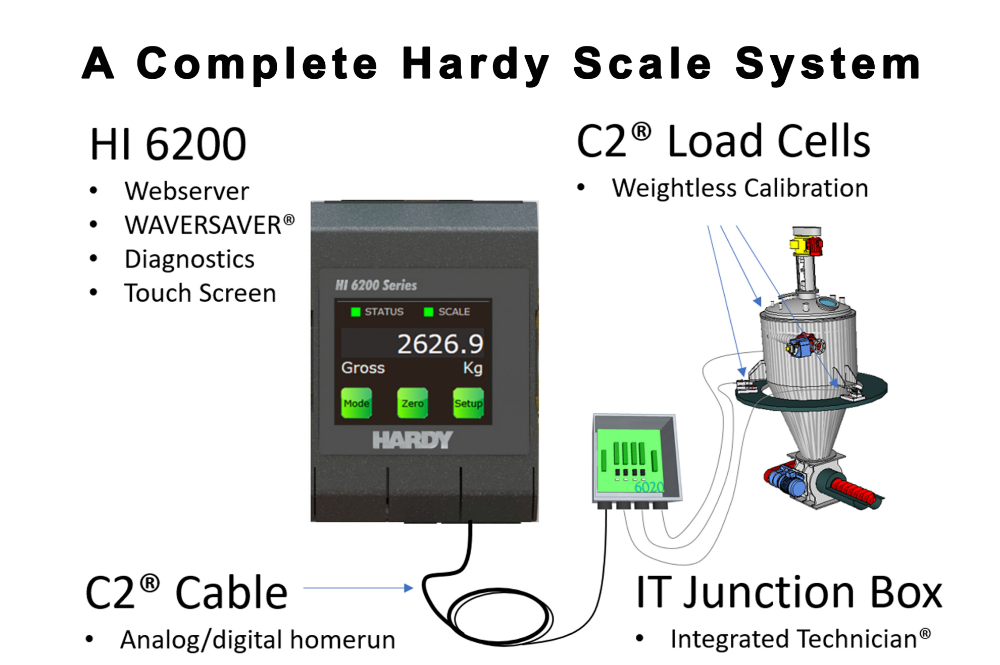

The Hardy HI 6200 series includes high-performance single-channel Weight Processors (featuring EtherNet/IP or PROFINET) or Weight Transmitters featuring 4-20mA Analog communications.

The EtherNet/IP and PROFINET HI 6200 models enable IIoT (Industrial Internet of Things) compatibility, remote diagnostics, 32-bit ARM Core processing, a 100 Hz update rate, and a color touch-screen display.

Watch the HI 6200 YouTube video

Book a One-on-One Virtual Demo to See the HI 6200 in action!

Take the HI6200 for a Test Drive

The HI 6200 4-20mA Analog is designed to replace signal conditioners and analog strain gage transmitters, providing OEMs, Systems Integrators, or machine builders the advantage of C2® Electronic Calibration. The color touch screen display also enables Zero and Tare, which are not functions typically available directly on Analog transmitters.

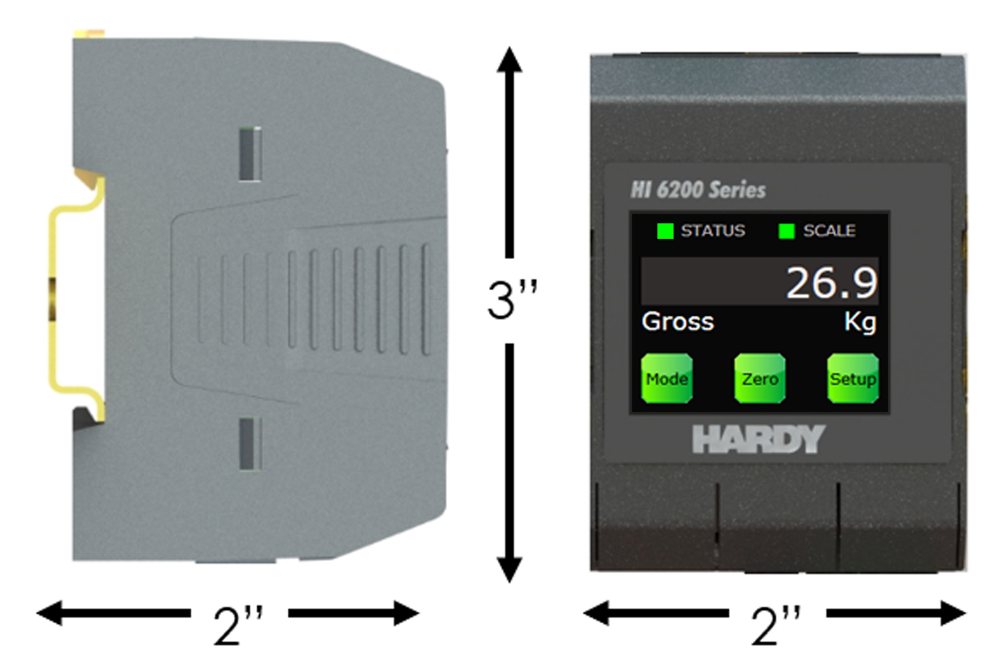

Ultra-compact at just 2 inches wide and 3 inches high (without connectors), the HI 6200 series saves cabinet space, allowing for high density panel design over traditional weighing instrumentation, reducing both machine cost and control cabinet footprint.

The HI 6200 series is designed to replace signal conditioners and analog strain gage transmitters with clean 4-20mA Analog signals or fieldbus connectivity. The HI 6200 series enables users to reap the benefits of IIoT device level connectivity through a built-in Webserver or directly via the UDP Transport Layer.

EASE OF USE

The intuitive 1.8” TFT-LCD touch screen interface is thoughtfully designed so that anyone with basic scale knowledge can set up and operate the instrument without having to read a manual or receive instruction. Despite its tiny size, the high contrast color TFT display provides crisp easy-to-read measurements and instrument status.

SOLID PERFORMANCE

Powerful 32-bit ARM Core processing or 16-bit processing (Analog models), state-of-the-art hardware design, combined with Hardy’s WAVERSAVER® technology ensure fast stable weight readings in even the most adverse conditions that often plague process control. As a co-processer to a control system such as a PLC, DCS, or PAC, the HI 6200 delivers 100 updates per second of processed weight data at resolutions exceeding 1:10,000 without placing additional burden or delay into control loops that depend on accurate, stable, and fast weight readings from analog sensors.

HARDY PROCESS TOOLBOX

All versions include the Hardy Process Toolbox, a proprietary set of productivity tools that includes C2® weightless calibration, WAVERSAVER®, Integrated Technician system diagnostics, and a suite of control integration tools such as a Rockwell EDS_AOP, Faceplates, and PROFINET GSD files. The Analog Version features C2® zero and tare functions through the TFT display.

Resolution

- Stable processed weight 1:10,000

- Maximum displayed resolution: 1:999,999

- Internal resolution 1:8,388,608

Update Rate

- Processed weight, display & comms: 100 times p/sec (50 times p/sec for Analog)

- Unprocessed weight (A/D conversion): 4800 times p/sec

Modes

- Gross, Net

Units of Measure

- Ounce, Pound, Ton, Gram, Kg, Metric Ton

Weight Processing

- WAVERSAVER®: 0.25 Hz to 7.5 Hz

- Averaging:1 to 255 User-selectable in single increments

Color Touch Screen Display

- 500:1 contrast ratio with 1.8" effective viewing area

- 128 x 160 pixels, 65K colors

- Resistive Touch Display

Calibration Methods

- C2® calibration without test weights

- Traditional calibration with test weights

Excitation

- 5VDC

Number of Load Cells

- Up to 8 at 350 Ω

Mounting

- DIN Rail

Communications

- EtherNet/IP (-EIP models)

- Ethernet UDP

- Ethernet TCP/IP (Embedded Webserver)

- Modbus TCP (-EIP models)

- Analog 4-20mA (-ANA models)

- PROFINET

Communication Interface

- Terminal, RJ-45

Power

- 12-24 VDC

- 3 watts nominal (EIP & ANA)

Temperature

- -10°C to +55°C (14° F to 133F)

Humidity

- 0-90% non-condensing

Dimensions

- 2.07” W x 3.37” H x 1.98” D (without connectors) (52.6 mm x 75.0 mm x 50.3 mm)

Approvals:

- UL, CUL Ordinary Location

- CE

- ODVA Level III

- RoHS3 & REACH

- Class I, Division 2 Groups A, B, C and D, Temp Code T6

- PI PROFINET

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves you time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including WAVERSAVER® to eliminate vibration, C2® electronic calibration, and Integrated Technician® to name just a few.

The HI 6200 series features the following Toolbox technologies:

WAVERSAVER® Vibration Eliminator

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display individual system weights and voltages, as well as pass/fail, stability, and zero verification to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.

Embedded Web Server

Access your instrument from any computer browser, easing setup and making diagnostics fast and easy. Use the Embedded Web Server to set up all password-protected parameters from anywhere on the Ethernet network. The web server also enables IIoT connectivity to The Connected Enterprise.