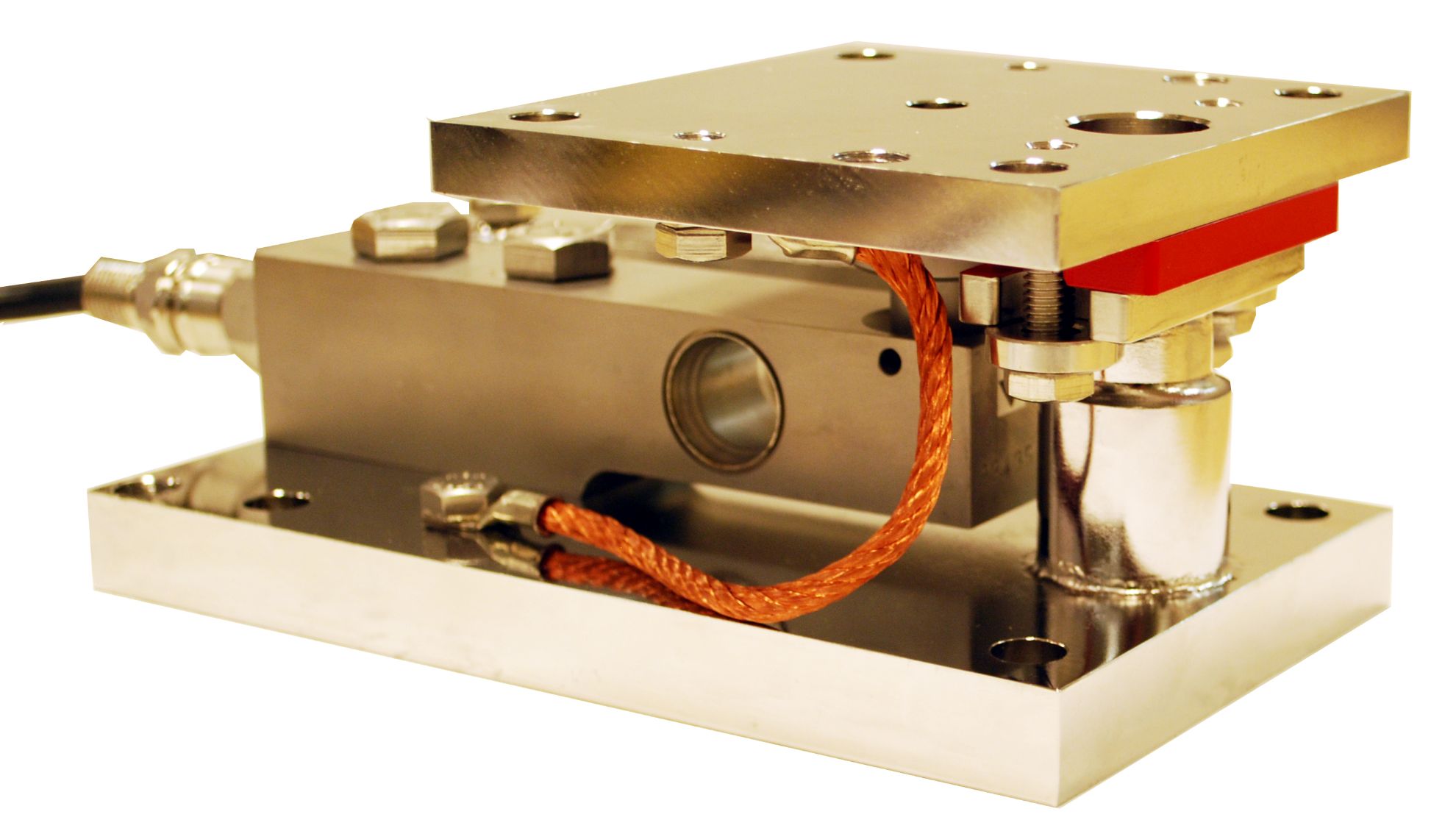

The Hardy OneMount™ with either Advantage® HISBH04 or Advantage® Lite HISB05 shear beams are specifically built to save customers time and money during installation, calibration, and maintenance. Each load point provides extraordinary flexibility and durability in most industrial environments. Each feature of the load point was intentionally designed based on nearly 100 years of process weighing experience, delivering a best-in-class measurement system for vessel, hopper, and tank weighing.

Accurate Load Cells

- Self-centering rocker design maintains alignment under considerable shear forces

- Precision sensor (combined error 0.02% rated output) from 1,125 lbs – 22,500 lbs

- Optional Dynamic Stabilization Rods can be purchased to reduce vibration noise on the sensor for better resolution

Safety

- Liftoff and side force ratings are confirmed by third party destructive testing

- True glass-to-metal hermetically sealed sensors deliver the ultimate washdown protection (IP68/IP69K)

- C2® electronic calibration reduces the risk of accidents or contamination from test weights

Easy Installation

- Integral spacers can carry the full rated capacity without the load cell installed, eliminating the need for expensive dummy load cells or welding fixtures

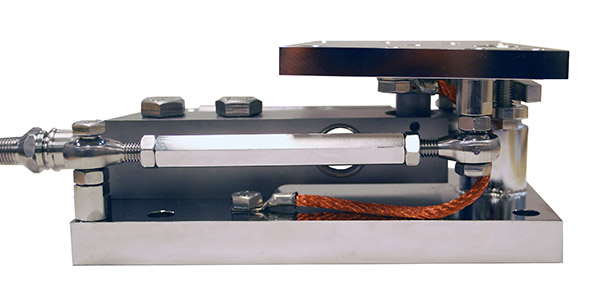

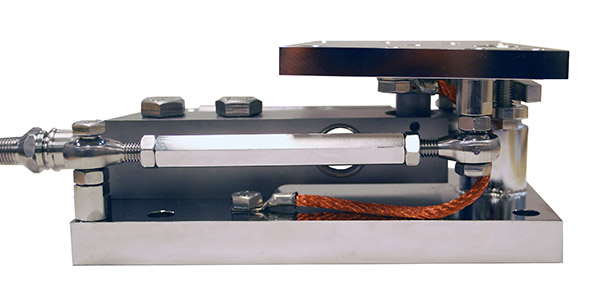

- Once mounts are installed, the load cells slide into place. With minimal tank jacking (1/8”), the spacers are removed for a live load point

- 360° checking mechanism means load points can be installed in any direction

- C2® electronic calibration for fast startup in high capacity installations

Easy Maintenance

- Replace load cells with minimal tank jacking (1/8”)

- Matched mV/V/ohm load cells are easy to replace without recalibration

User Benefits

- OEE improvement from consistent, accurate performance, and reduced installation and maintenance time

- Reduced capital investment and labor typically associated with dummy load cells and welding fixtures

- Reduced complexity of system selection and installation from a single, universal design

- Accurate load cells for a wide range of applications

See Our YouTube Video on the Safe, EASY and Accurate OneMount!

Easy Installation Process

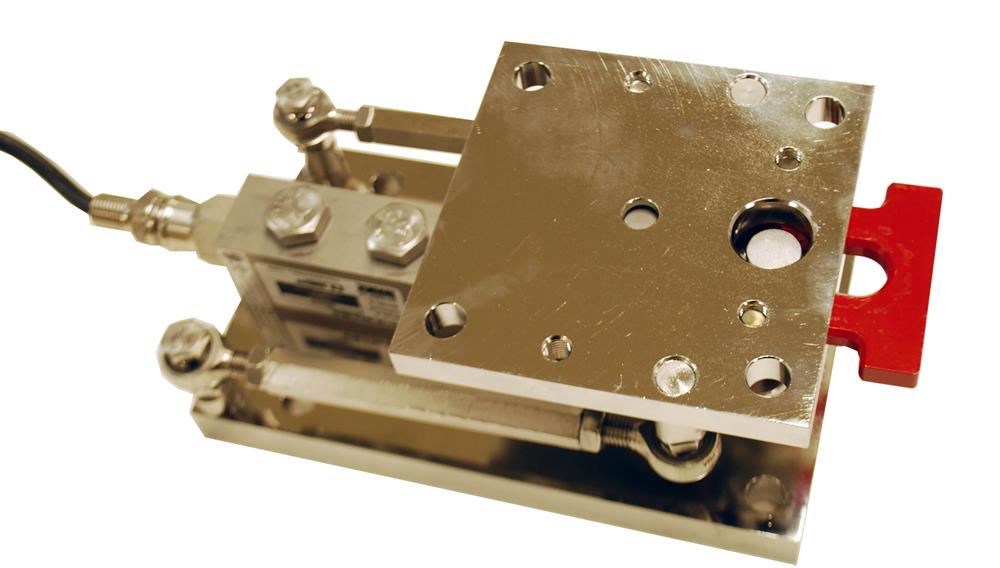

- Align and level the mounts under the vessel without the load cells installed. The mounts can be installed in any orientation, because of a 360º checking mechanism to ensure accuracy and safety.

- Lower the vessel onto the mounts and weld or bolt the mounts to the foundation and the vessel.

- Perform any peripheral pipe welding or add any required attachments.

- Slide the load cell into place and fasten to the bottom plate.

- Jack the vessel up 1/8” to remove the shipping/installation bracket.

- Lower the vessel onto the live load point and calibrate using Hardy’s C2® electronic calibration.

Call us today to see how the Hardy OneMount can solve all your tank, vessel, and hopper weighing needs! (858) 278-2900

Specifications Load Sensor: HI SBH04

Specifications Load Sensor: HI SBH04

Maximum Capacity (Emax) in lbs: 1.125k / 2.25k / 4.5k / 11.25k / 22.5k

Max number verification intervals nmax: 3000

Min load cell verification interval vmin: Emax / 11000

Combined Error: %RO ± 0.0200

Non-Linearity: %RO ± 0.0166

Hysteresis: %RO ± 0.0166

Creep error (30 Minutes) / DR: %RO ± 0.0166

Temp effect on min dead load ouput: %RO/10°C ± 0.0127

Temperature effect on sensitivity: %RO/10°C ± 0.0100

Non-Repeatability: %RO Not Specified

Rated Output (RO): mV/V 2 ± 0.1%

Calibration in mV/V/Ω: Matched

Zero Balance: %RO ± 5

Excitation Voltage V: 5-15

Input Resistance Ω: 1100 ± 50

Output Resistance Ω: 1000 ± 2

Insulation resistance (100VDC) MΩ: ≥ 5000

Load Cell Safe Load Limit %Emax: 200

Load Cell Ultimate Load Limit %Emax: 300

Load Cell Safe Side Load %Emax: 100

Compensated Temperature Range °C: -10 …+40

Operating Temperature Range °C: -40…+80

Load Cell Material Stainless Steel: 17-4PH (1.4548)

Sealing Complete Hermetic Sealing: Glass to Metal Header

Protection according to EN 60 529: IP68 (up to 2m water depth) / IP69k

Cable Length: 20 ft

Hazardous Certification: IS Class 1,2,3 Div 1

Legal For Trade: NTEP COC 99-057A1

Specifications Load Sensor: HI SB05

SPECIFICATIONS Units HI SB05

Maximum Capacity (Emax) lbs 22 / 44 / 110 / 220 / 440 / 550

Max number verification intervals nmax 3000

Min load cell verification interval vmin Emax / 11000

Combined Error %RO ± 0.0200

Non-Linearity %RO ± 0.0166

Hysteresis %RO ± 0.0166

Creep error (30 Minutes) / DR %RO ± 0.0166

Temp effect on min dead load output %RO/10°C ± 0.0140

Temp effect on sensitivity %RO/10°C ± 0.0100

Non-Repeatability %RO Not Specified

Rated Output (RO) mV/V 2 ± 0.1%

Calibration mV/V/Ω Matched

Zero Balance %RO ± 5

Excitation Voltage V 5-15

Input Resistance Ω 380 ± 10

Output Resistance Ω 350 ± 3

Insulation resistance (100VDC) MΩ ≥ 5000

Load Cell Safe Load Limit %Emax 200

Load Cell Ultimate Load Limit %Emax 300

Load Cell Safe Side Load %Emax 100

Maximum Platform Size N/A N/A

Compensated Temperature Range °C -10 …±40

Operating Temperature Range °C -40…±80

Load Cell Material Stainless Steel 17-4PH (1.4548)

Sealing Complete Hermetic Sealing - Glass to Metal Header

Protection according to EN 60 529 IP68 (up to 2m water depth)

Cable Length ft 10 ft

Hazardous Certification IS Class 1,2,3 Div 1

OneMount HIONEMT Specifications

SPECIFICATIONS Units HI ONEMT

Capacity 1125lb to 4500lb

Rated Liftoff Force lb 2250

Rated Overload lb 6750

Rated Side Force lb 4500

Weight Excluding Load Cell 9 lbs

Capacity 11250lb

Rated Liftoff Force in lb 5625

Rated Overload in lb 16875

Rated Side Force in lb 11250

Weight Excluding Load Cell 24lb

Capacity 22500lb

Rated Liftoff Force in lb 11250

Rated Overload in lb 33750

Rated Side Force in lb 22500

Weight Excluding Load Cell 43lb

For all Capacities:

Metallurgy Available: Electropolished Stainless Steel / Stainless Steel / Plated Steel

Levelling Required 0.4/100 (legal for trade) / 0.8/100 (general applications)

The Hardy Process Toolbox is a set of productivity tools that support industrial weighing functions. Each tool saves time, increases accuracy, improves efficiency, or reduces risk in process weighing applications, including C2® electronic calibration, and Integrated Technician® to name just a few.

Hardy load cells support the following Hardy Process Toolbox functions when coupled with a Hardy Instrument and Hardy C2® cable.

C2® (or eCAL) Electronic Calibration

The Hardy C2® (or eCAL as it is known in China) core feature provides quick and easy electronic calibration of a weighing system without the need for heavy test weights.

INTEGRATED TECHNICIAN® Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. These tests display system weights, voltages, and pass/fail displays to help isolate a problem to the instrument, cabling, or sensors, helping to reduce maintenance costs.