OBSOLETE, NO LONGER AVAILABLE

Note: The HI 2160RCPlus rate controller has been phased out and replaced by the more powerful, feature-rich HI 4060 rate controller. This information is provided for users of the HI 2160 RC Plus.

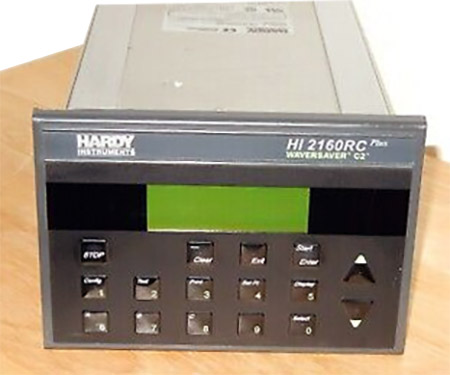

The HI 2160RCPlus rate controller is a compact, single ingredient Loss-in-Weight controller for use in a variety of applications, including auger, belt, pump, and vibratory-based feeders.

The key ingredient to the HI 2160RCPlus' ability to accurately control feed rate, is the use of WAVERSAVER® to ignore the effects of plant and process noise. WAVERSAVER® deciphers the incoming load sensor signal and distinguishes noise from actual forces on the scale.

As a result, the HI 2160RCPlus ignores severe plant vibration, mechanical motor noise, gear mesh vibration, and agitator activity, while detecting minute forces applied to the scale. WAVERSAVER® allows the HI 2160RCPlus's control algorithm to quickly correct the actual changes in rate instead of reacting to process noise.

The HI 2160RCPlus has been designed for the realities of the workplace with a waterproof front panel and tactile response keys. Operation is straightforward and easy to follow from the 80-character backlighted display. Frequently changed parameters are readily accessible, while one-time configuration data is logically arranged in a menu format. All data is protected against tampering with three user-defined security codes.

Automatic Control Mode

- Automatically corrects for variations in desired flow rates.

WAVERSAVER®

- Ignores plant and process vibration for more accurate measurement of feed rates.

Manual Control Mode

- Use the up and down arrows to manually control the flow rate. Convert to automatic mode when proper flow rate is achieved.

Continuous or Batch Modes

- User selectable operating modes for continuous or batch processing.

Automatic Refill

- User selectable refill points to start and stop the refill process. HI and LO alarms to detect a refill failure.

Manual Refill

- Allows for manual refill at any time.

Automatic Tuning (Auto Rate Calibration)

- Provides the user with automatically calculated parameters or the user can manually enter their own derived values.

Operation Displays

- Single button selection of Predefined operating displays such as Rate, Current Weight, Totalized Weight, and Batch data.

Secure Memory Module

- Provides for stored critical data to be transferred to a replacement HI 2160RCPLUS. Conveniently located on the rear panel, replacement takes only a few seconds. Does not require recalibration of the scale. Maximizes up time for the feed systems.

Control Output

- Electrically and optically isolated, user selectable 0-20 mA, 4-20 mA, 0-5 VDC, or 0-10 VDC output.

Front Panel

- 5" x 7" Waterproof when mounted in a NEMA 4 enclosure.

Serial Communications

- A bi-directional serial port (RS 232) allows the reading of data and downloading of feed rate instructions.

Hardy Link Communications

- Assigns addresses to each instrument so they can share the same Serial Chain.

Self Test

- Users can easily troubleshoot the controller by implementing the internal self-test.

Reports

- Automatically prepares batch performance reports.

C2 Second Generation Calibration

- Electronic method for calibrating a scale.

Remote Operation

- The HI 2160RC PLUS is fitted with a bi-directional serial port, an optional Allen Bradley I/O card, or Profibus Interface, which allows for remote operation of the controller.

Multiple Configuration Storage

- Stores up to twelve different complete system configurations allowing fast and easy transition to new material, auger, or entire feeder.

Two Sigma

- The Two Sigma Test feature is used to measure the feed rate performance for any given feeder system. The Two Sigma Test can be run on demand during all feed cycles.